Cable glands in high-voltage on-board electrical systems?

Surprising answers to crucial questions.

What are the basic wiring requirements for high-voltage on-board systems in commercial vehicles with alternative drives?

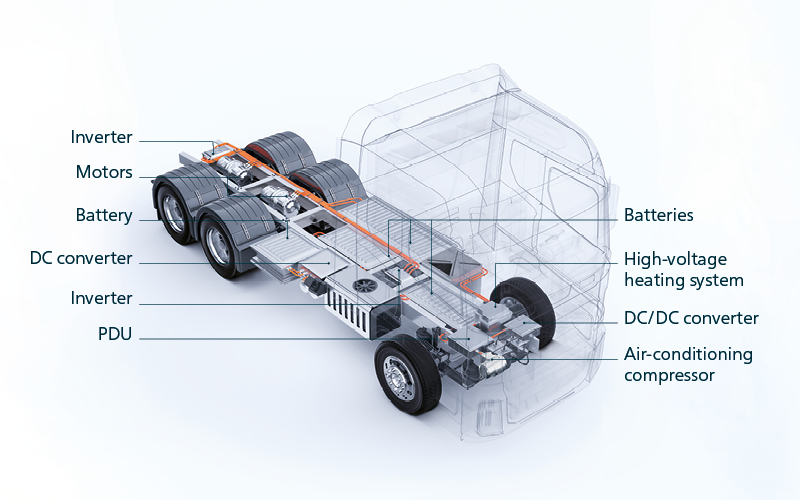

The wiring in high-voltage on-board electrical systems needs to be extremely efficient and durable. At the same time it must be able to withstand different kinds of high stress. For example, there may be high current flows on the cable shielding and electromagnetic interference signals produced by the drive components may impair the function of the wiring. And finally, the wiring is exposed to vibrations and extreme temperature changes. All these factors influence the reliability of assemblies, which have to meet increasingly rigorous requirements.

Connectors have been the component of choice here until now. Why?

In the automotive industry, the connector system is well-established and widespread in low-voltage on-board electrical systems. And this is why it was adopted as an obvious solution. Of course, it is a convenient solution – at first glance. However, cable glands offer a number of significant advantages over connectors. For example, cable glands guarantee high flexibility in their areas of application and they can be used individually with all common cable sizes without any problems.

What are the potential risks of using high-voltage connectors?

Connectors have the disadvantage of additional contact points where transition resistances can occur. This leads to losses and heat generation. In addition, specially trained personnel are needed to fit them.

Why are PFLITSCH EMC cable glands superior to other solutions on the market?

The sophisticated EMC cable glands from PFLITSCH make a major contribution to the safety of high-voltage on-board electrical systems as they provide outstanding attenuation and high current carrying capacity. They build up lower contact resistances than connectors, preventing losses and heat generation that affect power and data transmission. This means that the high quality of the system is not impaired with Cat. 7A signal cables. In addition, there are economic advantages such as straightforward cable termination that does not require highly qualified personnel, and the flexibility to cover large shielding and sealing areas with one cable gland.

And finally, there is another special feature that underlines PFLITSCH’s EMC competence – KoKet. This special test procedure developed in-house allows the shielding effectiveness of the cable glands to be precisely measured. The advantages: The cable has no influence on the measurement result, good reproducibility is guaranteed and measurements on cable glands up to size M85 are possible. This gives customers the reassurance that PFLITSCH EMC cable glands are working safely.

Request sample box!

Request an electric mobility sample box with the PFLITSCH AE blueglobe TRI HTS now, free of charge and without obligation. Simply fill out the form at the bottom of the website.

A high-voltage on-board electrical system has its own laws –

especially for EMC design.

In addition to great temperature changes, strong vibrations and the effects of lubricants and service fluids, the high-voltage on-board electrical system must be able to withstand electromagnetic interference signals and unwanted shield currents. The interference signals are produced by the components of the high-voltage on-board electrical system such as the high-voltage battery modules, electric motors and inverters. At the same time, the components of the electric drivetrain induce strong currents in the cable shield, bringing their current-carrying capacity to its limits. To guarantee the safety of the high-voltage on-board electrical system in all circumstances, PFLITSCH has developed EMC cable glands that safely discharge high-voltage interference and the currents on the cable shielding.

PFLITSCH EMC cable glands are superior to connectors – in many respects

Continuous cable to the main contact with lower contact resistances

Simple, quick and cost-saving assembly

Superior flexibility in use as there are solutions for all cable cross sections

High parts availability

Reliable 360° contact for safe discharge of interference radiation

High strain relief – even when subject to vibrations

Very robust to temperature changes, mechanical stress and the effects of lubricants and operating fluids

Our expertise leaves no questions unanswered – except:

What can we do for you?

Our many years of expertise in EMC not only make us a reliable partner for industry in general, they also make us the ideal partner for your particular projects when you need to develop a viable EMC design.

As a medium-sized company we are able to implement lean processes, which gives us a flexibility advantage over large manufacturers. We produce our solutions directly at our facility in Germany. This enables us to rely on stable supply chains, which means that you can rely on good security of supply and outstanding delivery performance.

Furthermore, you benefit from our comprehensive development approach which has enabled us to build up a perfectly coordinated range offering you a unique benefit: maximum compatibility.

Would you like to check out PFLITSCH cable glands as the safe choice for your high-voltage on-board electrical system?

Then request the PFLITSCH electric mobility sample box with the PFLITSCH AE blueglobe TRI HTS now, free of charge and without obligation.