Wire-tray Trunking from PFLITSCH –

open for safety and hygiene

Non-enclosed cable trunking system meeting the highest hygienic requirements

Processing and packing of products in the food, pharmaceutical and chemical industries must comply with numerous strict hygiene regulations. This applies to large sections of the production environment and also places high demands on the cable routing systems installed there. PFLITSCH has the perfect solution for requirements like these: our non-enclosed Wire-tray Trunking combines many different advantages and is convincing in every respect.

documentCreationDateTime: 2024-05-08

fileUploadDateTime: 2024-10-21

11.5 MB

EN

Orderly routing, thorough cleaning

PFLITSCH’s Wire-tray Trunking is the ideal solution to ensure orderly cable routing. Its non-enclosed design permits easy cleaning and it is therefore exactly right for use in the food and pharmaceutical industries. A coordinated range of accessories with hygiene-optimised fastening solutions and roof-shaped covers further adds to the exceptional hygienic design of this cable trunking system. However, our Wire-tray Trunking is also the perfect choice whenever your cables also need to have adequate air circulation or be constantly accessible.

Advantages of Wire-tray Trunking

Open, clear cable routing

Safe, ultra-stable and corrosion-resistant design in steel or stainless steel

Simple pre-assembly and installation using two tools and two connectors

Easy to clean for use in areas where strict hygienic requirements apply

Good air circulation avoids heat build-up

Comprehensive range of accessories, e.g. insertable separators and covers

Materials and sizes

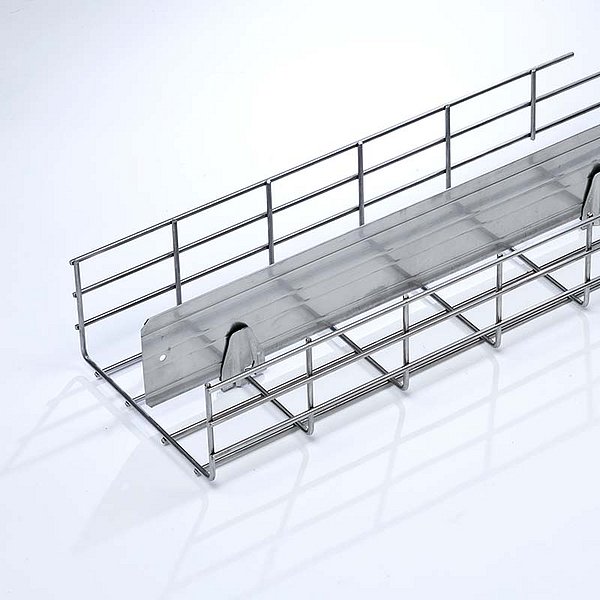

PFLITSCH Wire-tray Trunking is available in zinc-plated or hot-dip galvanised steel as well as in V2A stainless steel and an acid-resistant V4A version, which is ideal for the food industry, for instance. We supply our Wire-tray Trunking in a wide range of sizes and shapes, e.g. as Mini Wire-Tray Trunking from 40 mm x 20 mm to 65 mm x 30 mm, as a U-shaped system or in various L-shaped designs and even as flat trays. The Wire-tray Trunking in the GKX series is offered in the following sizes: from 53 mm x 46 mm to 620 mm x 110 mm, either as a U-shaped system or in a special G or C-shaped design.

Wire-tray Trunking – perfect for sensitive applications

Avoids heat build-up

The open, robust design of our Wire-tray Trunking does not simply allow easy insertion and removal of cables during laying or for maintenance and repair work. The excellent ventilation, which systematically avoids heat build-up, is another significant argument in its favour – and an unbeatable advantage especially in applications like IT or communications that are sensitive to heat. It also has UL and DNV approval for offshore use.

Easy to clean

Thanks to its non-enclosed design and the use of corrosion-resistant steel or stainless steel wire, which is additionally resistant to all common cleaning agents, our Wire-tray Trunking can be cleaned easily and thoroughly – also with a high-pressure cleaner or foam. Roof-shaped or flat covers are used to prevent dirt from settling and building up in case of horizontal installation, and to protect the cables laid in the trunking from mechanical stress or from liquids such as cleaning fluids dripping from above. A fully protected variant with side covers is likewise available. The covers are simply clipped onto the Wire-tray Trunking and also have the effect of increasing the installation’s overall stability.

Simple pre-assembly and installation

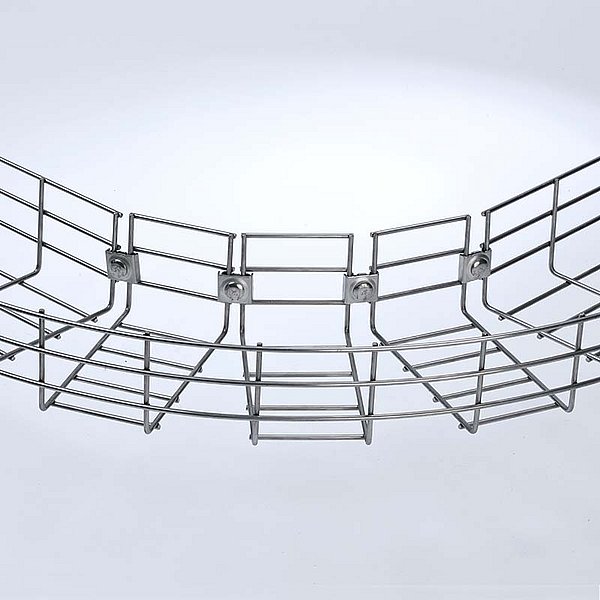

PFLITSCH Wire-tray Trunking consists of up to 6 mm thick, zinc-plated steel or stainless steel wire and combines optimal corrosion protection with high stability. It can be individually assembled using only two tools: in just a few steps, you can make bends, corners, offsets and reducers from a straight trunking section by cutting away any wire not needed with our Wire-tray Trunking shears. The segments are then screwed together with connectors and any open wire ends fitted with end caps.

Tools for Wire-tray Trunking

Using our mobile, electrohydraulic Wire-tray Trunking shears, you can easily cut away any wire not needed when your trunking is pre-assembled. These battery-powered shears with their special tool enable low-burr cutting of V2A, V4A or zinc-plated steel wire up to 6 mm in diameter – and finish the cut flush with the cross wire. The 330°-rotatable tool head is easy to use, even on already installed cable trunking.

Accessories

Radius limiters inserted at transitions and bends protect sensitive fibre-optic cables, for example, from damage. Insertable separators help route cables in an orderly manner in the Wire-tray Trunking. Universal mounting plates can be supplied for installing components directly at the trunking. And thanks to our special covers, you can protect the cables laid in the trunking from mechanical stress or from liquids such as cleaning fluids dripping from above. A fully protected variant with side covers is likewise available. The covers are simply clipped onto the Wire-tray Trunking components and also have the effect of increasing overall stability.

Fastenings range

PFLITSCH additionally has an extensive range of fastenings for Wire-tray Trunking, enabling rational and safe installation in all environments. They include mounting brackets, suspended cable supports, beams, holders, supporting feet and mounting plates. All fastenings for our Wire-tray Trunking systems are designed such that horizontal surfaces are reduced to a minimum. No impurities or cleaning fluids can collect there.

Component assembly service

More and more users are meanwhile opting for the PFLITSCH component assembly service. Ready-to-install Wire-tray Trunking component assemblies are supplied pre-assembled and on schedule according to each customer’s specifications. This significantly reduces the time customers spend on design and installation.

FAQ

Wire-tray Trunking is predestined for all applications requiring open, orderly cable routing and/or where exceptional hygienic design is essential, for instance in the food and pharmaceutical industries. Thanks to its non-enclosed design and the use of corrosion-resistant steel wire, it can be cleaned without any problem – also with a high-pressure cleaner or foam. It is additionally resistant to all common cleaning agents. The good air circulation avoids heat build-up and is another significant argument in favour of the non-enclosed principle. Wire-tray Trunking is thus ideal for use in the IT and communications industries.

In contrast to enclosed systems, which have a large number of accessory fittings, you can make bends, corners, cut-outs and junctions in the Wire-tray Trunking simply by cutting away any wire not needed with our Wire-tray Trunking shears. The segments are then screwed together with connectors and any open wire ends fitted with end caps.