Automobile-Trunking from PFLITSCH –

the walkable cable tray for production lines, not only in the automotive industry

The heavy-duty solution

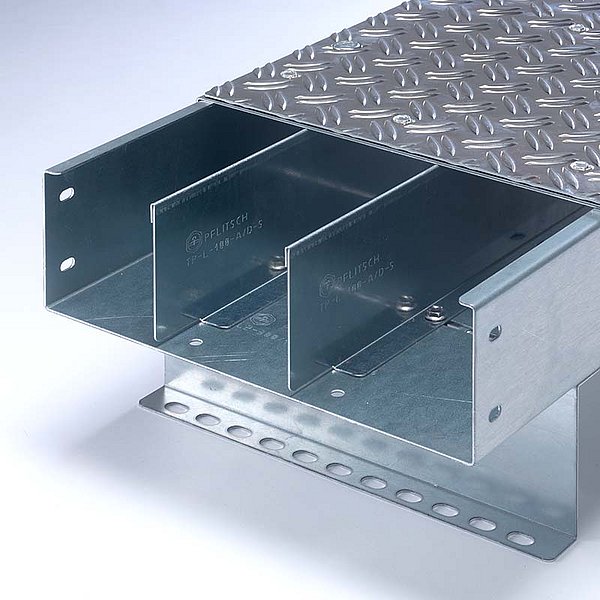

PFLITSCH’s Automobile-Trunking is the heavy-duty variant of the proven Industrial-Trunking. As floor trunking that is safe to walk on, it conforms to the works standards of numerous car manufacturers and meets the high requirements of this industry. Furthermore, it is now also used as anti-slip floor trunking in many robot cells and automated production plants.

documentCreationDateTime: 2024-05-08

fileUploadDateTime: 2024-10-21

3.7 MB

EN

Flexibility and safety with every step

Based on just a small number of system components, the walkable cable tray is a compact yet flexible system that allows you to create your own individual cable layouts quickly and easily with just a few accessory fittings. At the same time, you safe time and benefit from low costs for ordering, storage and installation. An aluminium channelled sheet covering fulfils the necessary anti-slip and walking safety requirements (R10 according to DIN 51130). With seven cross sections, with or without base perforation and universal separating walls, this robust cable trunking can be used almost anywhere indoors.

What does the slip resistance class R10 according to DIN 51130 mean?

In the DIN 51130 test, the floor covering is placed on a frame and doused with engine oil. While a tester walks over the floor covering, it is slowly raised to an increasingly steep angle. The angle at which the test person loses the slip resistance defines the class. R10 means: slip resistance up to an angle of inclination of 10° to 19°.

Your advantages at a glance

Walkable floor trunking with high footfall load

High strength, wide support spacing

Channelled sheet/claw plate for anti-slip protection/class R10 tested according to DIN 51130

Clear system for efficient ordering, storage and installation

Simple, fast and cost-effective installation

Can be combined with other PFLITSCH cable trunking systems

2 mm sheet thickness for greater stability

The floor trunking is precisely manufactured out of 2 mm thick, zinc-coated sheet steel and is therefore extremely robust. It can easily withstand footfall loading of up to 1,200 N and can also be installed with larger support distances, saving you time and money during the installation. When used with variable connection plates, the Automobile-Trunking can be aligned at any angle between 90° and 180°.

7 cross sections for a wide range of applications

The standard Automobile-Trunking is 100 mm high. When floor-mounted with 90 mm support legs and channelled sheet covering it has a step height of less than 200 mm. Seven cross sections with widths from 100 mm to 600 mm are available as standard, optionally with a closed or perforated base:

- 100 mm

- 150 mm

- 200 mm

- 300 mm

- 400 mm

- 500 mm

- 600 mm

Different cables in one cable trunking

Separating walls can be placed in various positions using the optional variable base perforation in the trunking. This allows different types of cables, such as energy, control and data cables or lines carrying fluids or compressed air to be kept apart from one another in several flexibly adjustable chambers to achieve EMC compliance. Our small cross section PIK-Trunking can be integrated into this system, thus allowing sensitive cables to be placed in closed inner cable trunking.

Tools

With PFLITSCH tools, you can easily adapt the robust Automotive-Trunking to your specific requirements on-site. The appropriate notching tool allows you to notch lateral cut-outs from cable trunking bodies conveniently and efficiently in order to feed cables in or out while the hole punching tool is used to punch connecting holes in the body elements. In addition, there are other little helpers, such as the rapid fixing tool and the combined open-ended wrench/flexible-head socket wrench, which make everyday tasks easier for you.

Fastenings – a coordinated range

The walkable Automobile-Trunking is designed for floor installation. For safe and simple installation on machines, in plants and industrial buildings, we have a range of high-quality fastenings that is constantly being expanded and is compatible not only with Automotive-Trunking, but with all PFLITSCH cable trunking. This eliminates the need for you to design expensive fastening systems yourself and minimises installation times. The high strength of the tried-and-tested fastenings in combination with the excellent robustness of the Automotive-Trunking allow large support spacings, which help you to reduce installation times and costs.

FAQ

The walkable cable trunking – also called Automotive-Trunking – is the heavy-duty version of the PFLITSCH Industrial-Trunking. Made of galvanised sheet steel with a wall thickness of 2 mm, it is so robust that you can walk on it without any problems.

The Automobile-Trunking can withstand footfall loading of up to 1,200 N (approx. 120 kg).

You can lay all kinds of different cables and lines in the Automobile-Trunking: power, control and data cables as well as fluid and compressed air lines. Our small cross section PIK-Trunking can be integrated into this system, thus allowing sensitive cables to be placed in closed inner cable trunking.

A range of fastenings is available for the installation of the Automobile-Trunking which also fits all other PFLITSCH cable trunking.

As tools we recommend the notching tool for making cut-outs in the trunking body and the hole punching tool to punch connecting holes in the trunking elements. The rapid fixing tool and the combined open-ended wrench/flexible-head socket wrench facilitate simple tasks.

The Automobile-Trunking is available in 7 sizes with a width of 100 mm to 600 mm and a height of 100 mm. It is exclusively manufactured in sheet steel with a wall thickness of 2 mm.

The walkable Automobile-Trunking is available with or without base perforation. The base perforation enables you to mount separating walls or support legs and profiles.