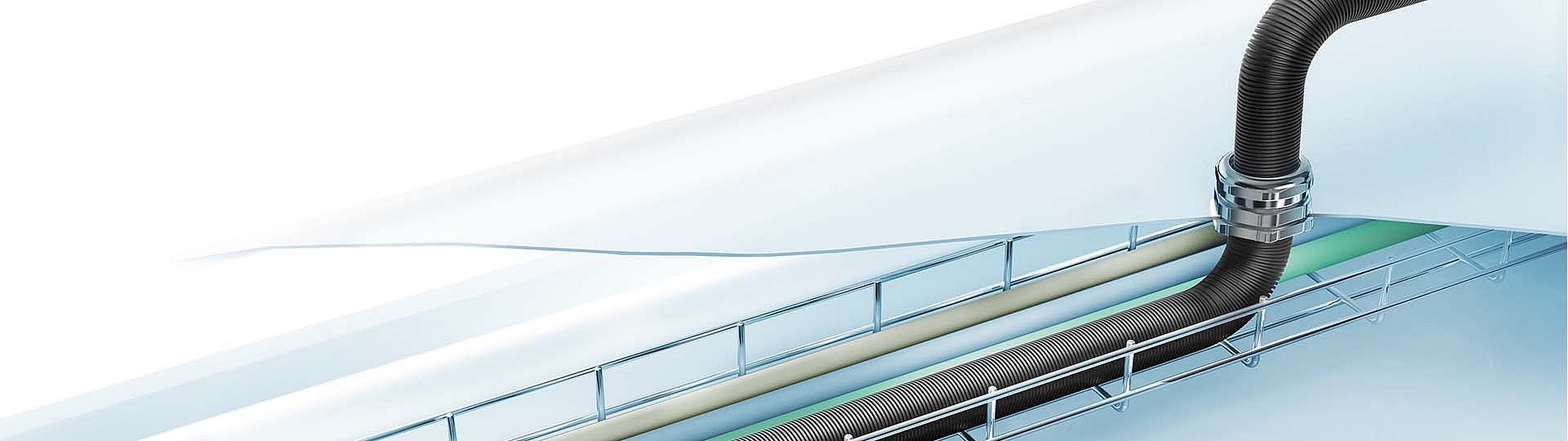

PFLITSCH corrugated conduit transit

Cable protection that goes through roof and wall

The insertion and continuation of cable-protecting corrugated conduits through the roofs and walls of railway vehicles poses special challenges – not only in terms of fire protection, but also in terms of tightness and installation safety. With the new fire protection-certified PFLITSCH corrugated conduit entry system, you now have a simple, safe and efficient way of inserting and continuing corrugated conduits through roofs and walls in rail vehicles.

documentCreationDateTime: 2024-05-08

fileUploadDateTime: 2022-12-12

1.0 MB

EN

Advantages

Conformity to EN 45545-2, hazard level HL3, thanks to sealing inserts made of fire protection silicone

Pre-assembled corrugated conduits can be installed even if they are too long

Reliable tightness, as the corrugated conduit sealing inserts are precisely matched to the corrugated conduit

Can be combined with other UNI Dicht components, e.g. for EMC protection or to seal multiple cables

Type of protection IP 68

Flexible and modular solution

Simple and safe installation

Space-saving and lightweight

Variability from the UNI Dicht modular system

The corrugated conduit transit is based on the UNI Dicht modular system and offers a whole range of unique advantages: Corrugated conduits can not only be inserted with the corrugated conduit cable gland, but also fed through completely and without interruption, ensuring complete cable protection. Pre-assembled corrugated conduits can also be installed without any problems despite their excess length. The corrugated conduit sealing inserts made of special fire protection silicone comply with fire protection standard 45545-2, hazard level HL3. They are slotted and precisely matched to the profiles of the corrugated conduit to be fed through. They are easy to install using ‘on block assembly’ and ensure excellent tightness. The flexible and modular solution also saves space and is extremely lightweight, with an attractive cost-benefit ratio. Another plus point: If further requirements are needed, such as secure EMC shielding, this can be easily realised by combining with other UNI Dicht components.

Technical data

- Material: nickel-plated brass

- Type of protection: IP 68 up to 10 bar

- Temperature range: –55 °C to +180 °C

- Sizes: M20 to M63

- For standard corrugated conduits with a fine and coarse profile in nominal diameters 10 to 48

Suitable corrugated conduits

The PFLITSCH corrugated conduit cable gland is designed for PFLITSCH corrugated conduits as well as for common PMA corrugated conduits. PFLITSCH corrugated conduits are characterised by their particularly high impact resistance, weather resistance and long-term stability and guarantee reliable protection of the cable installation. They have proven themselves not only in railway technology, but also in mechanical and plant engineering as well as in automation and robotics with their sometimes extreme dynamic loads.

Our corrugated conduits are available as standard in two variants and six corrugated conduit sizes. Other sizes are available on request.

Corrugated conduit, light

Properties

High pressure and impact resistance

Excellent weather resistance

Industry usage and properties

Mechanical engineering: yes

Robotics: no

Electrical: yes

Railway: yes

Automotive: yes

Maritime: yes

Flexibility: 1/6

Fatigue/flexural fatigue strength: 1/6

Pressure/impact resistance: 5/6

Chemical resistance: 3/6

Weather resistance: 6/6

Corrugated conduit, medium

Properties

Above-average pressure and impact resistance

Excellent weather resistance

Industry usage and properties

Mechanical engineering: yes

Robotics: no

Electrical: yes

Railway: yes

Automotive: yes

Maritime: yes

Flexibility: 1/6

Fatigue/flexural fatigue strength: 1/6

Pressure/impact resistance: 6/6

Chemical resistance: 3/6

Weather resistance: 6/6